To improve the mass distribution of the rotor relative to the axis and achieve the purpose of dynamic balance of the rotor.

Dynamic balance test process

A. Dynamic balance test system construction

The whole test system includes:

1. Dynamic balance test components

2. Speed sensor: for dynamic balance, its vibration form is a first-order vibration signal, and the extraction of speed is used for the calculation of order signals on the one hand; On the other hand, it can also be used as a reference signal for phase reference;

3. Vibration acceleration sensor: used to extract vibration signals brought by dynamic balance. Generally, in order to have a better signal-to-noise ratio, the measurement point is required to be close to the balance surface of the bearing or bracket.

B, test speed selection

1. Use the common speed of the component under test;

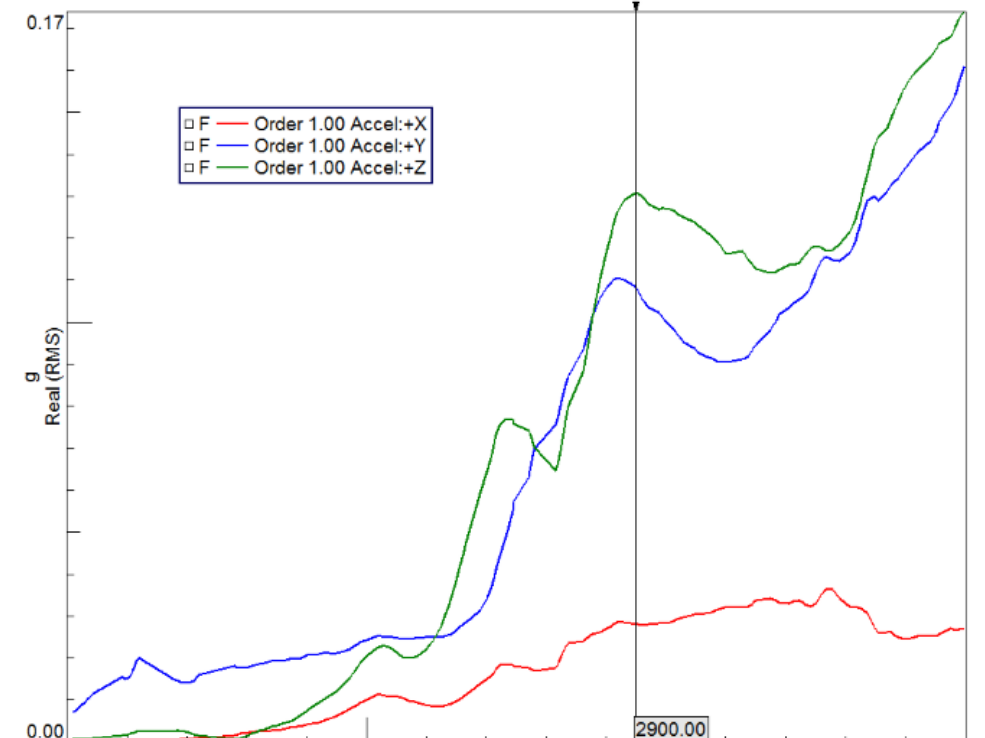

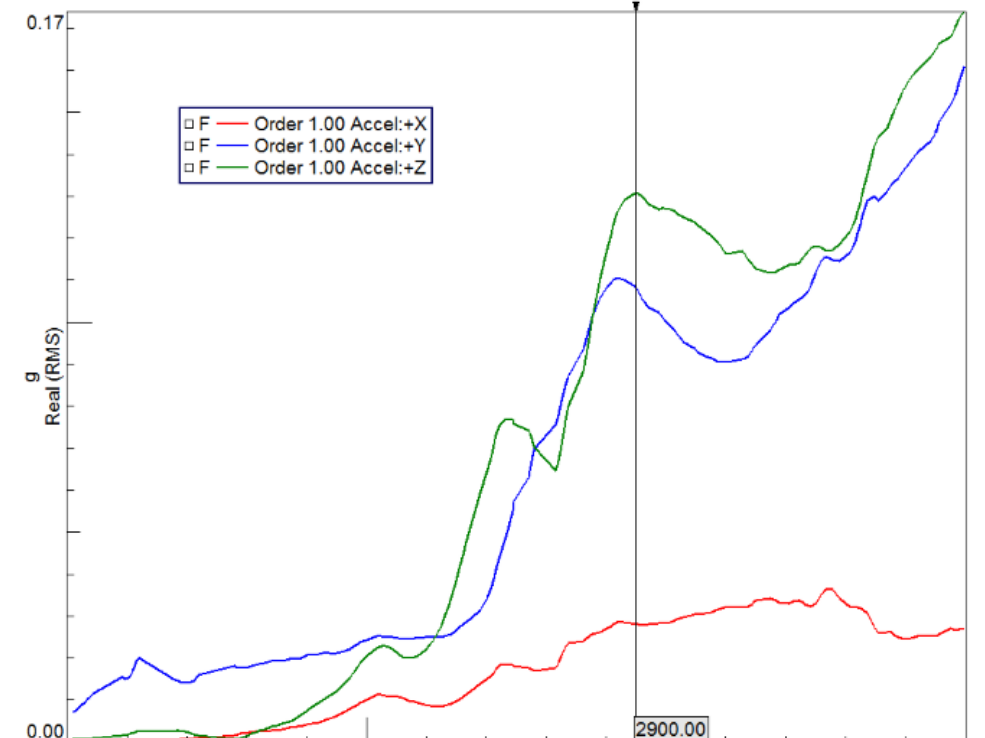

2. For dynamic balance, the centrifugal force will cause local deformation of the elastic components of the measured system, and then the first-order signal may have a peak value at a certain speed range (it needs to be determined that this phenomenon is caused by non-resonance). Extract the speed range that needs to be balanced, and select the test speed as 2900rpm as shown in the following figure.

C, test condition input

1. Select the rotational speed

2. Vibration signal selection

3. Dynamic balance surface selection

4. Determine the accuracy level of dynamic balance

5. Input relevant information of the balance block (weight of the balance block and specific position information on the balance surface)

D. Test procedure

1. The first order vibration amplitude and phase test of the original state under working conditions: multiple groups can be averaged, in order to obtain better results, it is recommended to test for more than 20 seconds each time;

2. Increase the first-order vibration amplitude and phase test of the mass block under working conditions: the mass of the mass block and the specific position on the balance surface are clear;

3. Based on the test results of step 1 and Step 2, the influence coefficient balance method is used to calculate the balance block and its specific position that meet the accuracy level of dynamic balance;

4. Based on the suggestion in 3, add the confirmation of the dynamic balance test results under dynamic working conditions of the balance block.