Today, with the rapid development of intelligent manufacturing and precision equipment, the performance of motors, as the core power and transmission components of various mechanical systems, has become a key yardstick for measuring the advancement of high-end equipment. At present, most of the competing products in the market focus on breaking through a single performance indicator, making it difficult to meet the urgent demand of cutting-edge equipment for a comprehensive performance leap.

Osens relying on its profound technological accumulation and forward-looking market insight, has successfully developed an abnormal sound detection device integrating "AI+ acoustics" on the basis of traditional detection equipment. This milestone product not only marks a major breakthrough for Ousens in the intelligent manufacturing upgrade of high-end equipment, opening up new application scenarios for AI technology in industrial application, but also brings a brand-new solution to the field of motor inspection.

Industrial abnormal noise detection, as a strategic direction of technological innovation, is breaking through the traditional performance boundaries through the deep integration of AI technology. Any abnormal sound in the motor may indicate potential quality issues with the product, which in turn can affect the user experience and even the reliability of the entire system. Traditional abnormal noise detection equipment is limited in detection accuracy and mainly relies on human hearing to distinguish the subtle differences in sound. It is difficult to accurately capture the subtle abnormal sounds in motors in complex and changeable industrial environments, and it cannot meet the strict requirements of quality control throughout the entire life cycle of transmission components in the era of Industry 4.0.

Problems and Challenges of Traditional Detection

Subjectivity: People's emotions, experiences and individual differences lead to inconsistent criteria for judging abnormal sounds. Decibel detection equipment can determine the decibel value of noise, but it cannot identify specific abnormal sounds such as friction sounds, resonance sounds, and whistling sounds.

Efficiency and cost: Relying on "golden ears" for individual detection is time-consuming, labor-intensive and costly. The fast-paced and high-intensity assembly line work is prone to causing fatigue and misjudgment among inspection workers, resulting in the outflow of substandard products.

Audio quality: Due to the mechanical noise interference from real-time running production lines, related equipment, soundproof rooms, etc., obtaining high-quality product operation audio is a challenge, and corresponding audio noise reduction technologies need to be developed.

Technical difficulties: Traditional methods such as CNN or multi-layer perceptrons have difficulties in feature extraction and quantization when dealing with subtle abnormal sounds. Machine learning models are prone to overfitting and have poor generalization ability.

AI Reconstructs the Underlying Logic

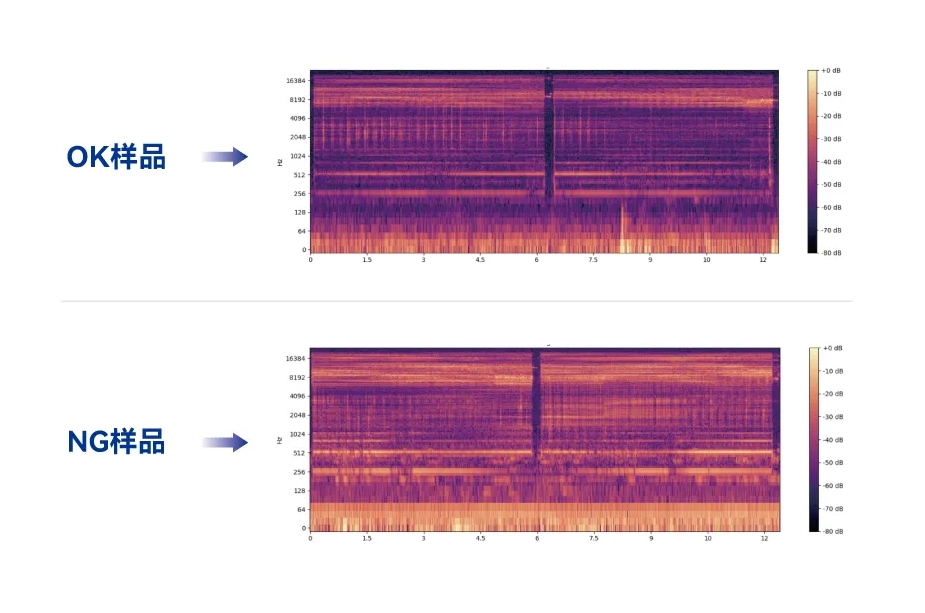

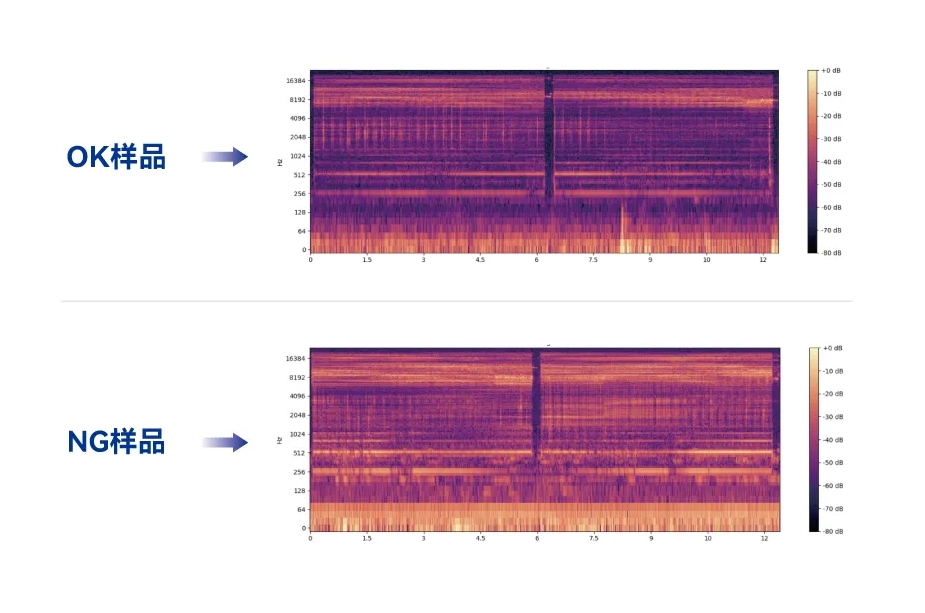

From the following analysis diagram, it can be seen that the sounds of the 0K sample and the NG sample have certain differences, but there are no obvious feature points to capture, which poses certain challenges when further identifying the sounds. To accurately grasp the differences between various sounds, it is necessary to explore more latent features.

To address the noise and other issues generated by industrial equipment, this scheme utilizes acoustic models for feature extraction and conducts regression analysis through statistical methods to establish a mathematical relationship between features and abnormal sounds. This technological innovation has significantly enhanced the detection accuracy.

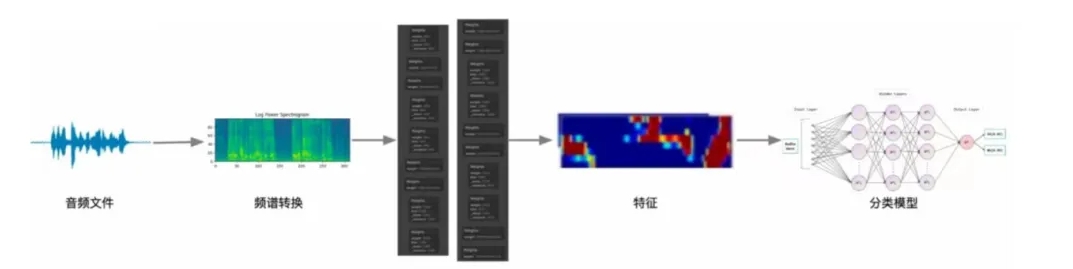

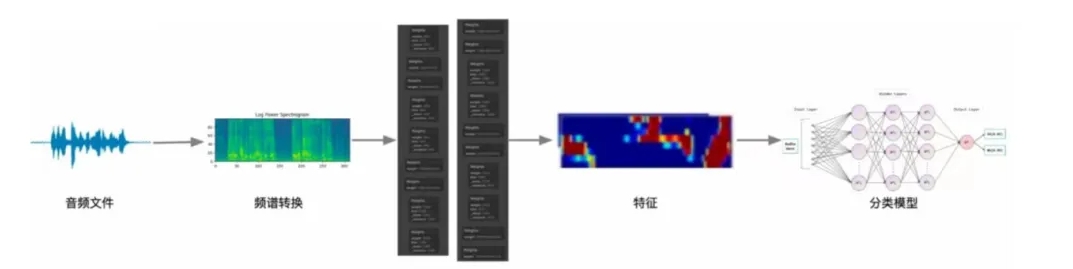

By collecting sound samples, audio files are converted into data formats suitable for model training. Subsequently, select the appropriate training model based on the characteristics of the data, such as deep neural networks, convolutional neural networks, or fully connected neural networks, etc. After conducting sound feature learning training using these models, the parameters of the obtained models are tuned to enhance their performance. The final output of the optimized model achieves efficient and accurate automated abnormal noise detection, providing reliable technical support for different application scenarios.

Abnormal Sound Detection Technology Based on AI Training

The key to distinguishing the quality of a motor lies in a precise assessment of its status. Technically speaking, it is similar to voice classification, and its core function is to identify the category or corresponding state/scene to which the audio signal belongs. When the brain receives sound information, it will recognize and categorize it. Similarly, in the detection of abnormal sounds in motors, the system makes detailed distinctions based on various characteristics of the sound (such as pitch, loudness, timbre, etc.), essentially classifying the sound signals.

The artificial intelligence abnormal noise detection technology based on acoustic feature analysis accurately discriminates the motor status by constructing a multi-dimensional audio feature model, effectively distinguishing between normal and abnormal motor states. Models trained based on large-scale acoustic data have strong generalization ability and can capture weak abnormal voiceprint features that are difficult for the human ear to identify in complex industrial environments. Compared with traditional detection methods, this technology conducts in-depth analysis of the spectral characteristics, energy distribution patterns and temporal variation laws of sound, significantly enhancing the sensitivity and accuracy of state recognition, and providing a reliable intelligent perception means.

Abnormal Sound Detection Software Platform

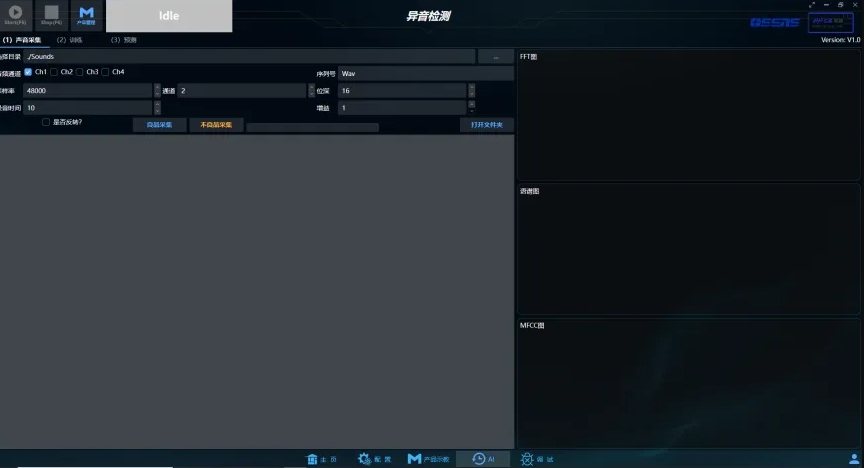

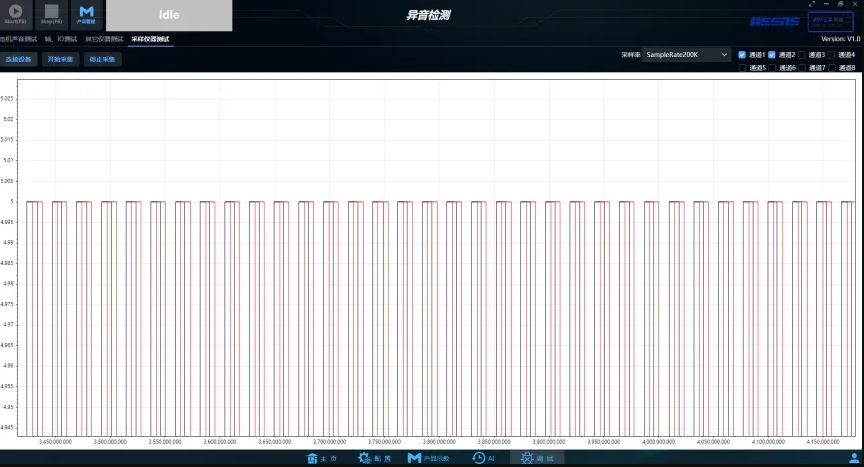

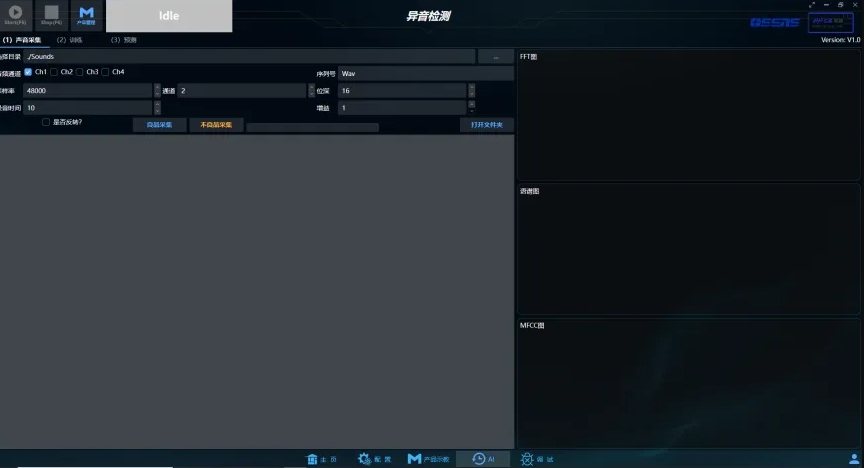

Audio Data Acquisition Platform

The self-developed acquisition software is deeply integrated with the self-developed audio acquisition equipment, achieving an integrated operation of audio acquisition and annotation, successfully solving the long-standing "difficult problem" in the industrial field.

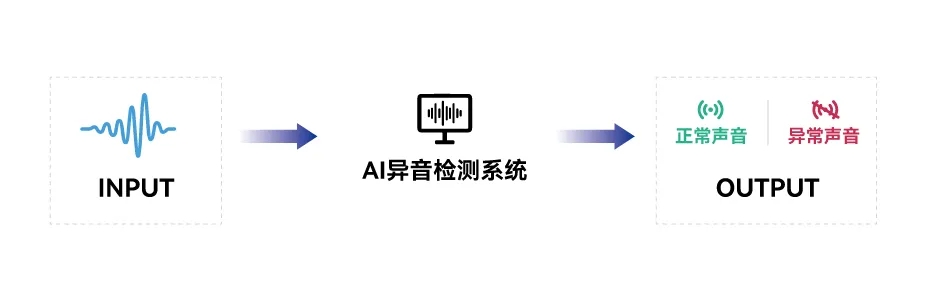

AI Abnormal Sound Detection Platform

Real-time abnormal sound detection of products is carried out, and deep learning algorithms are utilized to accurately identify abnormal sounds that occur during the operation of the equipment.

Motor Signal Detection Platform

Through real-time monitoring and analysis of signals, potential faults during motor operation can be detected in a timely manner, providing data basis for the performance evaluation and optimization of the motor.

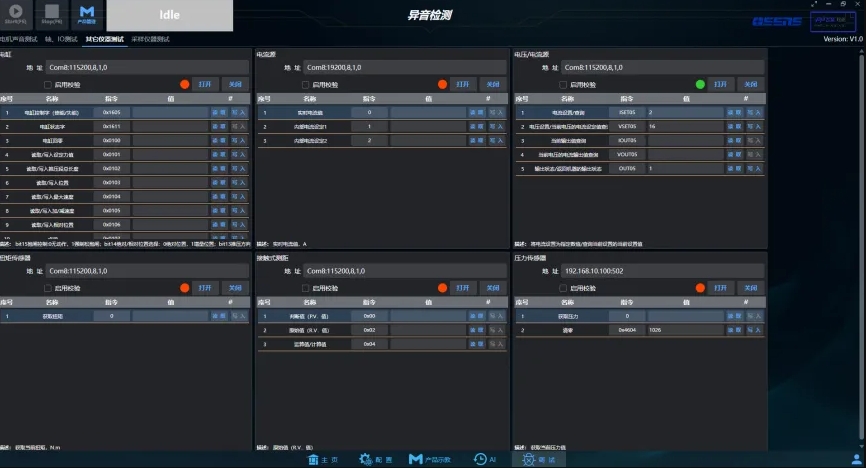

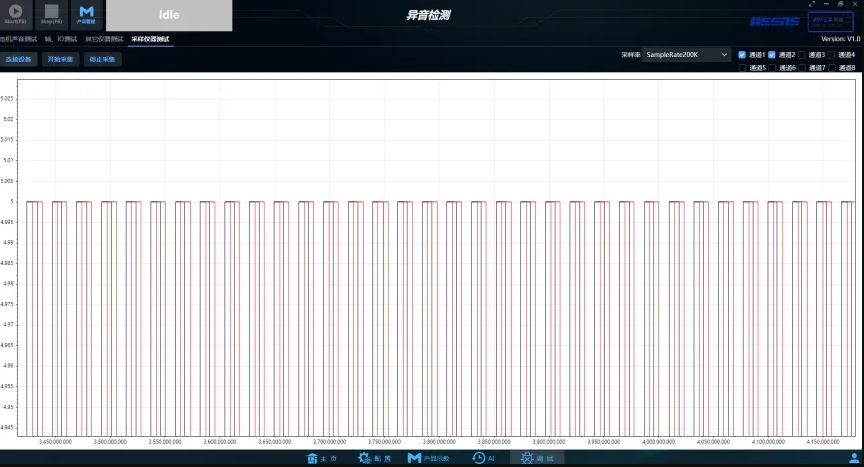

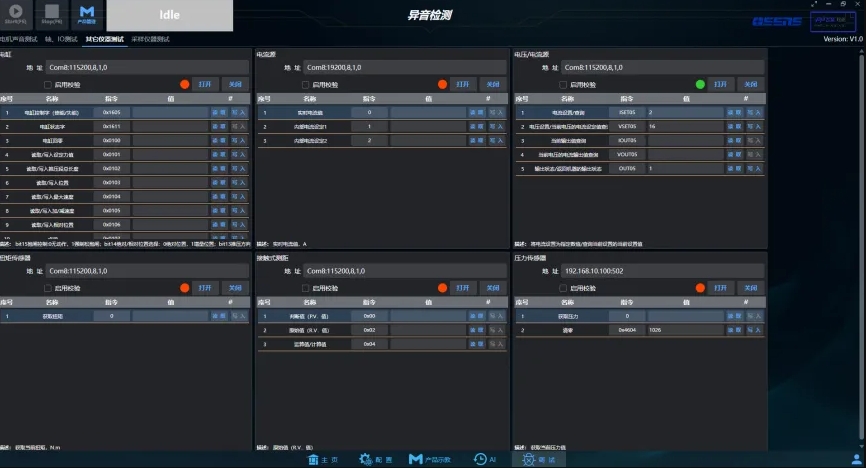

Instrument Debugging Platform

Provide comprehensive debugging functions for related detection instruments. On this platform, parameters can be set, calibrated and performance optimized for audio acquisition devices, AI abnormal noise detection modules, motor signal detection instruments, etc.

"AI+ Acoustics" Abnormal Sound Detection Equipment

By using deep learning algorithms, the accuracy rate has been increased by 30% compared with traditional algorithms

Realize real-time detection function, and shorten the detection time to the millisecond level

High-precision AcquisitionAccurately identify abnormal sounds, and integrate the audio collection and annotation process into a multi-functional system

Expansion of Multimodal detection

It has excellent scalability and can be applied to the detection of different types of equipment such as fans, blowers and toothbrushes

Drive New Quality Productivity With Intelligent Detection

In the development of the industry, the detection of invisible defects has always been a difficult problem to overcome. However, Osens has keenly captured this key pain point. We are well aware that true industry transformation often stems from precise control over the details. For this reason, Osens has continuously increased its investment in technological research and development, focusing on enhancing the intelligence and automation levels of detection technology. It actively responds to the national call to promote new industrialization, develop new quality productivity, and accelerate the renewal of industrial equipment, integrating the concept of "Made in China" into every detail of detection technology. In the future, Osens will continue to uphold the development philosophy of "innovation-driven and quality-oriented", constantly promoting the continuous innovation and application of intelligent manufacturing technology, and keep moving forward on the path of capturing invisible defects, enabling intelligent manufacturing to evolve from "hearing clearly" to "hearing accurately".